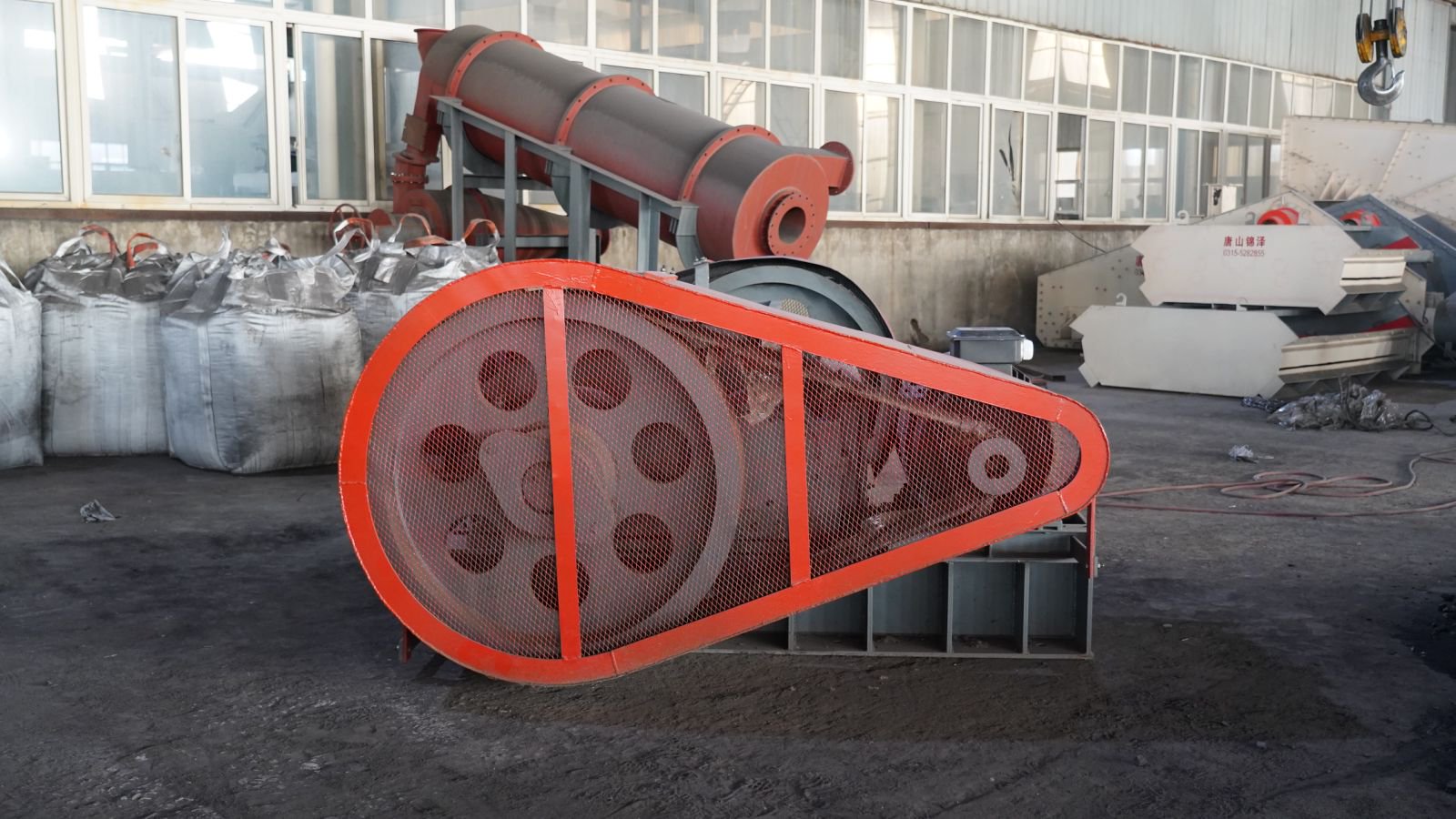

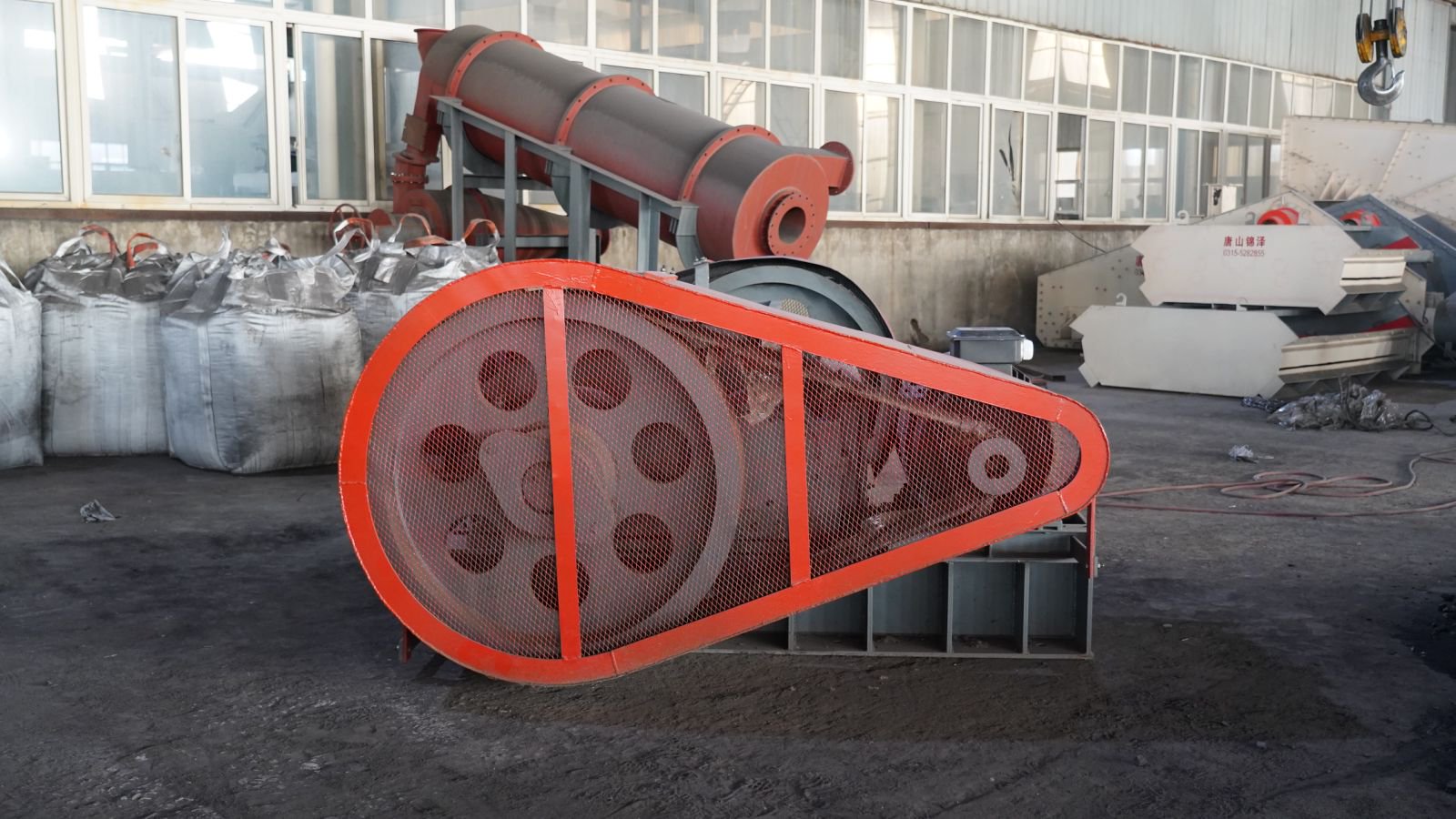

High-Efficiency 2PGC Double-Tooth Roller Crusher

Industry Background and Market Demand

In mining and mineral processing, crushing efficiency has a direct impact on overall plant productivity, energy consumption, and operating cost. As resource extraction shifts toward lower-grade deposits and more complex raw materials, operators increasingly require crushing equipment that can deliver predictable output while maintaining mechanical reliability under continuous load. At the same time, stricter environmental regulations and cost-control pressures have reduced tolerance for excessive fines generation, unplanned downtime, and high maintenance frequency.

Within this context, roller-based crushing solutions have regained attention for their controlled crushing behavior and relatively low energy consumption. The high-efficiency 2PGC double-tooth roller crusher addresses these demands by combining stable throughput, adjustable product size, and durable construction, making it suitable for medium and fine crushing stages in modern mining operations.

Core Concept and Crushing Technology

The operating principle of a 2PGC double-tooth roller crusher is based on compression and shear rather than impact. Two toothed rollers rotate toward each other at a controlled speed, drawing material into the crushing zone. As material passes between the rollers, it is fractured along natural weakness planes, producing a more uniform particle size distribution.

This crushing mechanism offers two important advantages. First, energy input is applied gradually, reducing unnecessary breakage and fines. Second, the adjustable gap between rollers allows operators to control discharge size with high precision. In high-efficiency configurations, optimized tooth geometry and synchronized drive systems further improve material grip and throughput stability, particularly when processing brittle or moderately hard materials.

Product Structure, Performance, and Manufacturing Process

The high-efficiency 2PGC double-tooth roller crusher is typically composed of a reinforced frame, roller assemblies, drive unit, adjustment system, and overload protection components. Each element is designed to operate under sustained mechanical stress while maintaining alignment and balance.

Rollers are manufactured from wear-resistant alloy steel or high-strength cast steel. Heat treatment processes such as quenching and tempering are applied to achieve a hardened surface with sufficient core toughness. This balance is critical for resisting abrasive wear while preventing premature cracking or deformation. Tooth profiles are machined or cast with tight tolerances to ensure even load distribution across the roller surface.

The frame and bearing housings are engineered to handle vibration and cyclic loads common in mining environments. Precision machining during manufacturing reduces assembly errors, which helps extend bearing life and ensures smooth roller rotation. In high-efficiency designs, attention to manufacturing consistency plays a key role in maintaining predictable performance over long operating cycles.

Key Factors Influencing Quality and Performance

Several technical factors determine whether a 2PGC double-tooth roller crusher achieves high operational efficiency in real-world conditions. Material characteristics such as hardness, moisture content, and feed size variation directly influence crushing behavior. Excessive moisture, for example, can lead to material adhesion and reduced throughput if not properly accounted for in tooth design and clearance settings.

Roller surface quality is another critical factor. Uniform hardness and accurate tooth geometry reduce uneven wear and maintain consistent crushing action. Adjustment system reliability also affects performance, as precise gap control ensures stable product size while preventing overload conditions.

Drive system matching is equally important. Motors, gearboxes, and couplings must be selected to deliver sufficient torque without excessive energy loss. Poorly matched drive components can lead to vibration, increased wear, and reduced efficiency.

Supplier Selection and Supply Chain Considerations

From a procurement perspective, selecting equipment based solely on nominal specifications often leads to performance gaps during operation. A qualified supplier of high-efficiency crushing equipment should demonstrate expertise in material engineering, manufacturing quality control, and application-specific customization.

For the 2PGC double-tooth roller crusher, supplier evaluation should include manufacturing consistency, roller material sourcing, and heat treatment capability. Access to spare parts, technical documentation, and long-term support also influences lifecycle cost and operational risk. Stable supply chains reduce the likelihood of extended downtime caused by component shortages, particularly in high-utilization mining environments.

Common Challenges and Industry Pain Points

Despite their advantages, roller crushers are not immune to operational challenges. Uneven roller wear, material clogging, and reduced efficiency under fluctuating feed conditions are common concerns. These issues often stem from improper tooth configuration, insufficient allowance for moisture, or misalignment caused by installation errors.

Maintenance planning is another frequent pain point. Crushers designed with limited access to rollers and bearings can increase service time and labor requirements. Addressing these factors during equipment selection and layout planning helps operators avoid unnecessary interruptions and maintain consistent production levels.

Application Scenarios and Industry Use Cases

High-efficiency 2PGC double-tooth roller crushers are widely used in coal preparation plants, industrial mineral processing, and pre-crushing stages of mining operations. Typical applications include size reduction prior to screening, preparation of feed for downstream grinding, and controlled crushing where excessive fines must be avoided.

In coal handling systems, the ability to maintain stable output size while accommodating variable feed conditions is particularly valuable. Similar benefits apply in limestone and other brittle material processing operations, where uniform particle size improves downstream efficiency and reduces energy consumption.

Current Trends and Future Development Directions

The development of crushing equipment is increasingly influenced by efficiency optimization and data-driven maintenance strategies. For roller crushers, this includes the use of advanced wear-resistant materials, improved sealing systems, and condition monitoring technologies that provide early warning of component wear.

Future designs of high-efficiency 2PGC double-tooth roller crushers are likely to incorporate enhanced modularity, allowing faster roller replacement and easier customization for specific materials. As mining operations continue to emphasize energy efficiency and operational transparency, crushers that combine mechanical simplicity with intelligent monitoring will become more relevant.

Frequently Asked Questions

What materials are most suitable for a 2PGC double-tooth roller crusher?

Brittle and semi-hard materials such as coal, limestone, and similar industrial minerals are commonly processed.

How does adjustment affect crushing efficiency?

Accurate roller gap adjustment ensures consistent product size and prevents unnecessary energy consumption.

What maintenance aspects are most critical?

Regular inspection of roller teeth, bearings, and alignment is essential for maintaining long-term efficiency.

By integrating controlled crushing principles with robust mechanical design, the high-efficiency 2PGC double-tooth roller crusher remains a practical solution for mining operations seeking stable performance, predictable maintenance, and efficient material size reduction.

Whatsapp

Whatsapp Утас

Утас